The process control of a sulfuric acid plant needs good and reliable detection of gas phase SO2. To measure SO2 is a challenge due to the corrosive environment and high concentration of SO2. Several places in the process need to be monitored and to transport the sample gas is difficult. A large dynamic range is needed as the SO2 concentration can vary between 15% volume and a few mg/m3. Most systems installed need a lot of maintenance, sometimes as often as every day.

The OPSIS DOAS system is different and provides sulfuric acid plants with an accurate analyser that can measure in temperatures up to 1000°C and with a maximum pressure of 1 Bar (G). The system operates with a minimum of maintenance.

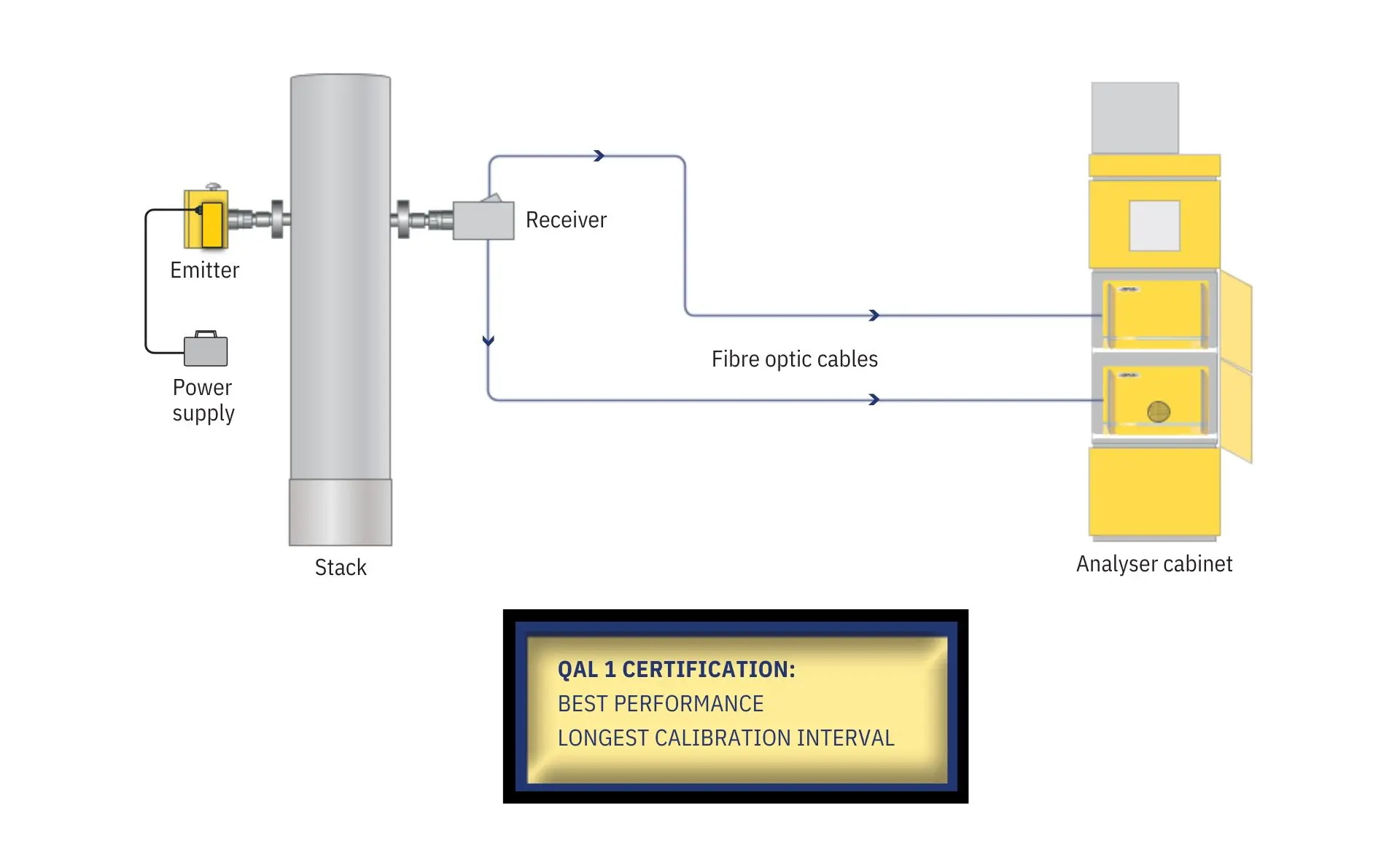

A typical service interval with an OPSIS system is 3 to 6 months. The OPSIS DOAS system is a non-contact method, using an optical measurement path that operates across a duct. The optical light is transported in an optical fibre to the analyser and one analyser can operate several paths. Besides the measurements of SO2, additional gases such as SO3, H2O and O2 can be measured.

Application sheet

System overview