The OPSIS Total Gaseous Mercury (TGM) Monitor (System 400HG) is an accurate mercury analyser that will operate with a minimal maintenance.

Monitoring of total mercury takes place in the clean gas, just before it is released into the ambient air. This provides monitoring of the flue gas treatment and that the emission limits are not exceeded. Waste incinerators, cement plants and power plants need good and reliable measurements of total gaseous mercury.

A total mercury monitoring system from OPSIS can easily be supplemented for monitoring of other types of gases. This provides a cost-effective and easy-to-maintain system for all emissions monitoring.

Notably, the OPSIS system can be supplemented for monitoring elemental mercury in the raw gas, immediately after combustion. The monitoring results are used to control flue gas treatment in real time, which often involves the injection of activated carbon.

How it works

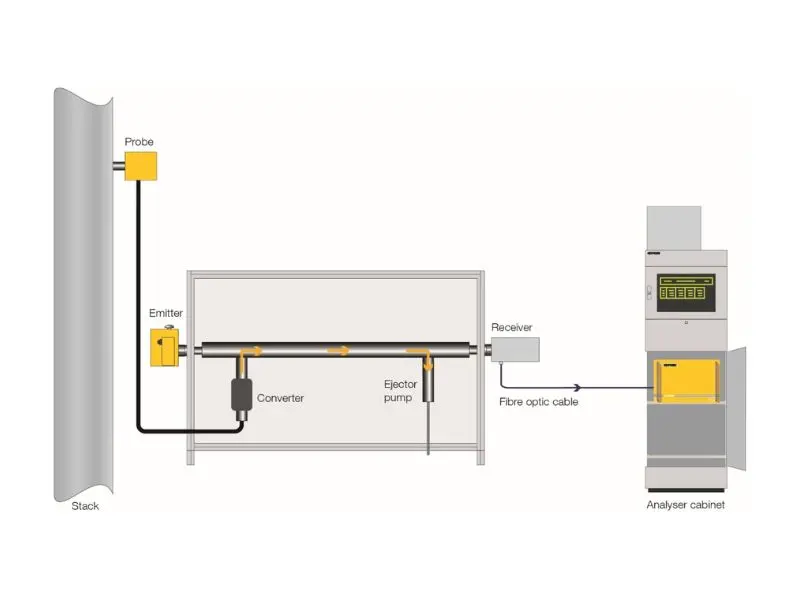

The OPSIS monitoring systems are based on gas analysers that have short response times, are accurate, and require minimal maintenance. The monitoring takes place contact-free along light beams where gas molecules can absorb parts of the light. In process monitoring of elemental Hg, light beams are sent through the gas duct or part of the gas is led into a measurement cell through which the light is led. When monitoring emissions of THg, part of the process gas is led via a converter into a measurement cell through which the light is sent. The light is captured and led via optical fibres to the analyser which measures the absorption and calculates the gas concentrations.

A single analyser can measure several types of gases in several gas channels. It provides a very cost-effective monitoring system. In addition to monitoring the levels of Hg and/or THg, the concentrations of many other types of gases can also be monitored, such as NOX, SO2, CO2, CO, NH3, H2O, HF, and HCl.

Data sheets and specifications are subject to change, and Cura Terrae Air cannot be held responsible for inaccuracies in manufacturer-issued data sheets. To confirm specifications and obtain the latest issue of the data sheet, please contact us.