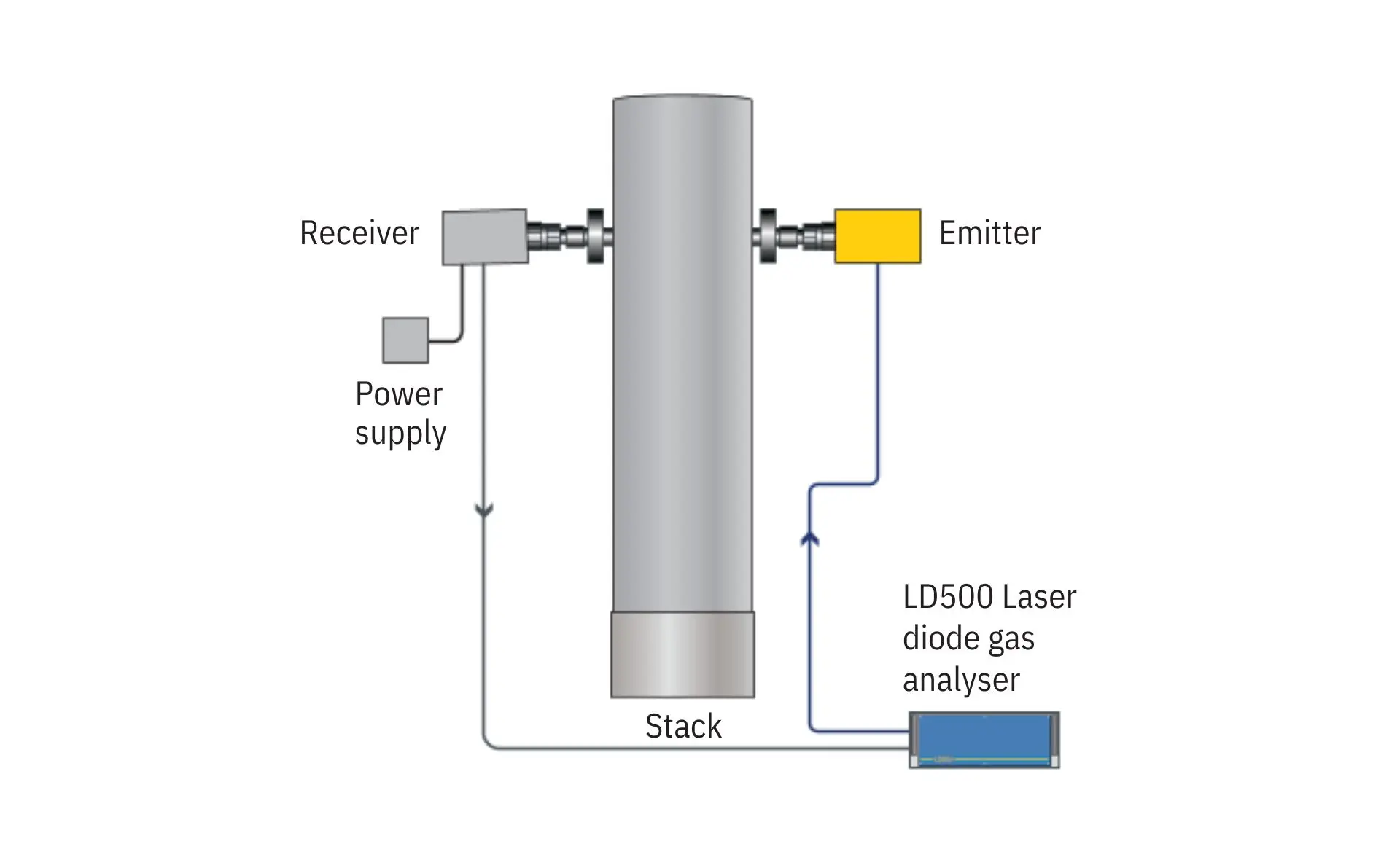

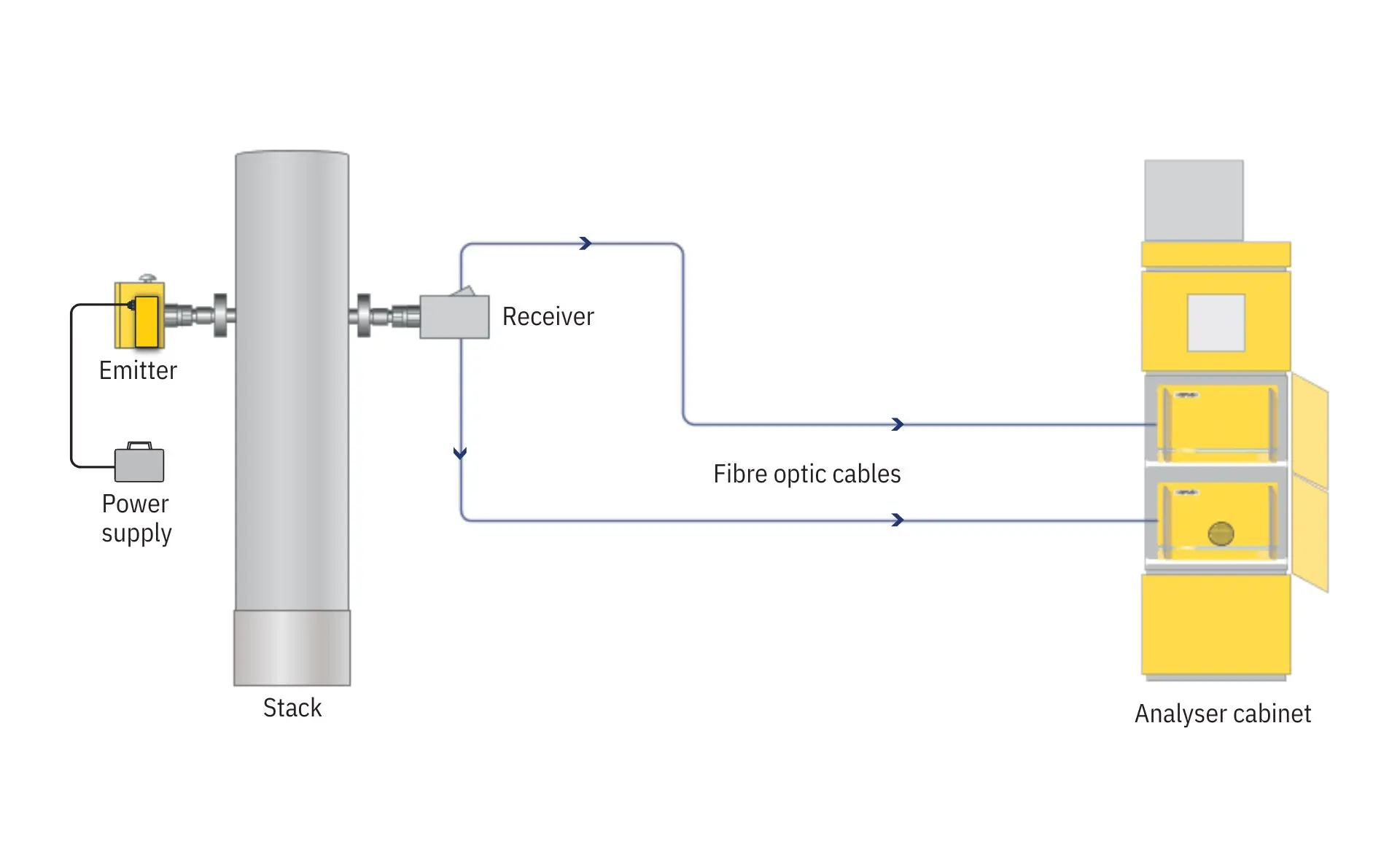

Process control and emission monitoring in a steel plant is a challenge. A large number of gaseous components need to be measured with high accuracy. The environment is corrosive with high temperatures and high dust load. To use an extractive gas analyser in this environment will require a lot of maintenance. The OPSIS Cross stack system is different and provides a gas analyser that will operate with a minimum of maintenance. The OPSIS cross-stack system is based on a non-contact DOAS, FTIR/TDL method using an optical path that can operate across the duct. The light is transported in an optical fiber to the analyser and one analyser can operate several ducts.

A single OPSIS system will measure all relevant gases, such as NO, SO2, CO, CO2, NH3, HCl, HF, O2, H2O and temperature.

Applications

- Electric arc furnace

- Coke plant

- Converter

- Sinter plant

- Steel production

- Steel rolling

Application sheet

System overview